Product introduction and main parameters

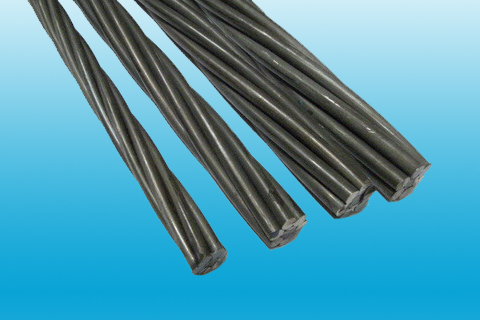

The mine cable is composed of steel strands, anchors and other accessories. Steel strands are strand-shaped prestressed steel wire strands twisted by several steel wires; anchors are permanent anchoring devices used to maintain the tension of the prestressed steel strands and transfer them to the reinforced rock formation.

The main technical parameters

(1) The resin anchoring agent used in the mine anchor cable meets the requirements of the MT146.2-2011 standard, the anchor cable anchorage meets the requirements of the GB/T14370-2007 standard, and within the validity period of the safety standard, the steel hinge wire meets the GB/T5224- 2014 standard requirements.

(2) The static load anchoring performance of the anchorage meets the following two requirements:

Ηa≥0.95 εpu≥2.0% ηa anchor efficiency coefficient, εpu is the total strain of the length of the assembly under the ultimate tensile force.

(3) The pull-out force Tw of the anchor cable should not be less than 1.05 times the designed load-bearing Nt of the anchor cable, and Tw≥1.05Nt.

|

Tensile strength of steel strand (MPa) |

1860 |

1770 |

1860 |

|

|

Strand diameter(mm) |

15.2 |

17.8 |

21.8 |

21.8 |

|

Pull-out resistance is not less than(KN) |

164 |

224 |

349 |

366 |

|

Pallet bearing capacity is not less than(KN) |

234 |

320 |

490 |

524 |

|

Stranded wire structure |

1×7 |

1×19 |

||

(4) The size of the pallet is not less than 150×150mm butterfly shape, the thickness is ≥15mm, the central aperture is 2~4mm larger than the nominal diameter of the steel strand, and the bearing capacity is ≥1.5 times the design bearing capacity of the anchor cable.

Scope of application

This product is suitable for the support of coal mine tunnel engineering and the earthquake-resistant reinforcement of buildings. It can be used in tunnels, tunnels and intersections with large surrounding rock deformation and poor geological conditions in coal mines, as well as surrounding rock fracture zones and stress concentration areas. It can also be used for building foundation pit reinforcement, slope treatment and various tunnels and bridges.

user's manual

(1) Select anchor cables and anchoring agents according to the design requirements, determine the location of holes and make marks. The hole diameter of the drill hole should not be less than the design value.

(2) Remove the floating dust and accumulated water in the hole with compressed air and install anchoring agent, and choose the amount of anchoring agent according to the length of the anchoring section.

(3) Use the stirring machine to drive the assembled anchor cable, and advance to the bottom of the hole while stirring. When the strength of the anchoring agent of the anchor and the pressure bearing seat reaches 15.0MPa, strong pulling can be carried out (the accuracy of the pressure gauge of the strong pulling equipment should not be less than 1.5, and the common reading of the pressure gauge should not exceed the table during the calibration interval 75% of the scale); the degree of tension is graded according to 0.20, 0.50, 0.75, 1.00, and 1.10 times the design load, and the load stabilization time with each level of tension is not less than 2min.

(4) During tension, the loading rate should not exceed 1/10 of the design load per minute, and the unloading rate should not exceed 1/5 of the design load per minute.

(5) After the prestressed tension ends, it must be checked that the exposed length should not be less than 30mm. Cut the exposed extra-long part.

|

Stranded wire structure |

Nominal diameter of steel strand |

Strand strength |

Maximum force of the whole steel strand |

The maximum value of the maximum force of the whole steel strand |

0.2% yield |

Maximum force total elongation% |

Stress relaxation performance |

|

|

The initial load is equivalent to the actual maximum force percentage/% |

1000h stress relaxation rate r/% |

|||||||

|

1×7 |

15.24 |

1860 |

260 |

288 |

229 |

3.5 |

70

80 |

2.5

4.5 |

|

17.80 |

355 |

391 |

311 |

|||||

|

18.90 |

409 |

453 |

360 |

|||||

|

21.60 |

530 |

587 |

466 |

|||||

|

1×19S(1+9+9) |

17.80 |

1770 |

368 |

410 |

334 |

|||

|

19.30 |

431 |

481 |

379 |

|||||

|

21.80 |

554 |

617 |

488 |

|||||

|

17.80 |

1860 |

387 |

428 |

341 |

||||

|

19.3 |

454 |

503 |

400 |

|||||

|

21.80 |

583 |

645 |

513 |

|||||

Scope of application

Prestressed steel strands are mainly used in prestressed reinforced concrete for roads and bridges, tunnels and mines, etc., to meet the country's demand for high strength and low relaxation prestressed steel strands for highways, railways, bridges, and dam construction.

user's manual

(1) Before construction, the test piece shall be taken for mechanical property inspection according to the provisions of the current national standard "Steel Strand for Prestressed Concrete" GB/T5224-2014, etc., and its quality must meet the requirements of the relevant standards.

(2) Anchors, clamps and connectors for prestressed tendons should be adopted according to the design requirements, and their performance should meet the requirements of the current national standard "Anchors, clamps and connectors for prestressed tendons" GB/T14370, etc.

(3) The anchors, clamps and connectors for prestressed tendons should be visually inspected before use, and the surface should be free of dirt, rust, mechanical damage and cracks.

(4) Fracture or slippage of prestressed tendons should be avoided during tensioning. When fractures and slippage occur, the specifications must be met. For pretensioned prestressed components, prestressed tendons that break or slip off before pouring concrete must be replace.

(5) When the construction requires excessive tension, the maximum tensile stress should not exceed the provisions of the current national standard "Code for Design of Concrete Structures" GB50010.