|

Project |

MZGK110-42/25 |

MZGK210-50/32 |

|

Rod outer diameter(mm) |

25 |

32 |

|

Rod inner diameter(mm) |

15 |

18 |

|

Wall thickness(mm) |

5 |

7 |

|

Straightness(mm/m) |

≤2 |

≤2 |

|

Screw pitch(mm) |

12.5 |

12.5 |

|

Thread height(mm) |

1.5 |

1.5 |

|

Rod length(mm) |

(1400~2600)±10 |

(1400~2800)±10 |

|

Minimum anchor length(mm) |

1000 |

1000 |

|

Applicable drilling diameter(mm) |

42 |

50 |

|

Rod maximum force(kN) |

≥110 |

≥210 |

|

Rod elongation(%) |

≥6.0 |

≥6.0 |

|

Anchoring force(kN) |

≥80 |

≥130 |

|

Threaded nut bearing capacity(kN) |

≥80 |

≥130 |

|

Pallet carrying capacity(kN) |

≥80 |

≥130 |

The scope of products:

It is mainly used for mine roadway reinforcement and slope protection of roads and bridge foundations. The hardness coefficient of the reinforced rock mass is <7.

Enterprise standard (Q/AKT10-2012 "Hollow Grouting Anchor Rod" and MT 146.2-2011 "Resin Anchor Rod Part 2: Metal Rod Body and Accessories").

User's manual

(1) Drilling: Drill and clear holes with a common rock drill.

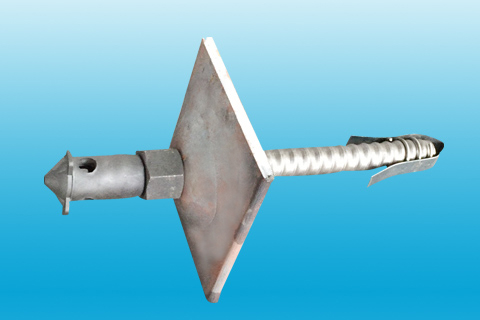

(2) Insert the anchor rod: Insert the hollow grouting anchor rod with the anchor head installed into the hole, and the barbs on the anchor head immediately hang the anchor rod.

(3) Install the slurry stopper, tray, and nut.

(4) Connect the grouting machine: connect the tail of the anchor rod to the selected grouting machine through a quick grouting joint.

(5) Grouting: ① The grouting uses bottom-up, left-right sequential operation. After the grouting is completed, determine whether to re-inject and re-inject according to the observation results. ② After connecting the grouting equipment, first use water to test injection. After confirming that the system connection is accurate and reliable, normal grouting can be performed. ③ Cement No. 425 is formulated into cement paste at a water-cement ratio of 1:1.5, and the grouting liquid prepared after stirring in the mixing container for 5 minutes. ④Turn the pump to grouting according to constant pressure and quantitative control. During the grouting process, the changes of each grouting parameter should be recorded at any time to observe the deformation of the roadway surface. If the leakage slurry or the roadway deformation or roof collapse are found, the injection should be stopped immediately. Pulp.