Product introduction and main parameters

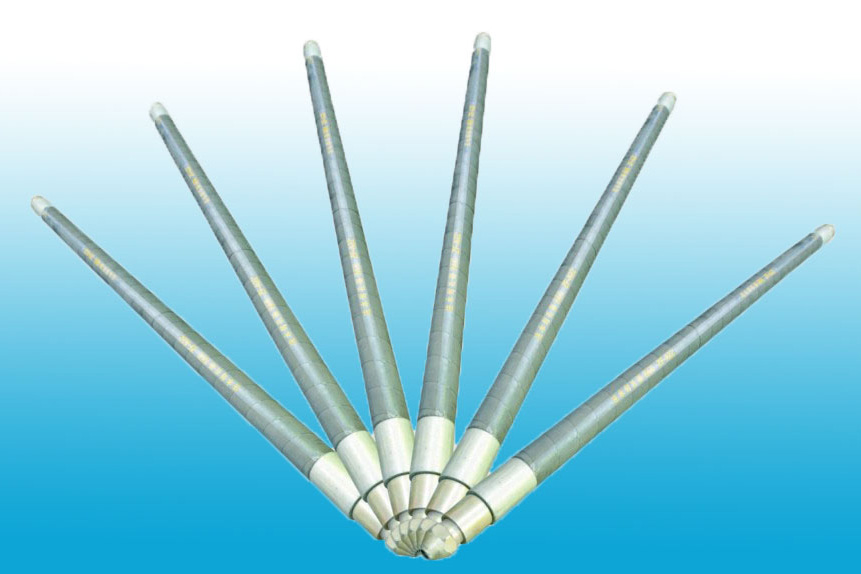

The FKSS type seam sealing device for coal seam injection is composed of high-pressure expansion hose, built-in safety valve, and quick connection pipe fittings. The product has a simple structure, is fast, simple, safe, reliable, and can be used repeatedly. It is an ideal product for coal seam water injection.

The main technical parameters

(1) Overall dimensions and allowable deviation (mm)

|

Model |

Length |

Outer diameter |

inside diameter |

Applicable aperture |

|

FKSS-39/8 |

L1=L0±10 |

39±0.8 |

22±0.8 |

40-70 |

(2) Type test

|

Test items |

skills requirement |

|

Free expansion outer diameter |

Fill the hole sealer to the designed working pressure and measure its free expansion outer diameter to be 76-90mm. |

|

Sealing performance |

The hole sealer is maintained at 1.1 times the maximum design working pressure for 5 minutes without leakage or other damage |

|

Minimum burst pressure |

Put the hole sealer into the steel pipe, flush to the minimum burst pressure of 24MPa, keep it for 5min, and do not break. |

|

Sealing force |

Put the hole sealer into the steel pipe sealed at one end, connect the hydraulic device, pressurize to the upper limit of the design working pressure of the hole sealer, start the timing and determine its initial position after keeping it for 3 minutes, and the time to 10 minutes, the recorded displacement value should be ≤ 5mm. |

|

Flame retardant performance |

Flame burning time and Mars burning time ≤30S |

|

Conductivity |

The arithmetic mean of surface resistance≤1×108Ω. |

Scope of application

FKSS type coal seam water injection hole sealer is used for coal seam water injection, water enters the coal body, releases part of the gas, and effectively reduces the gas content of the coal body. After water injection achieves the effect, it can reduce dust by more than 80%, improve the working environment of workers, and prevent dust explosion accidents. It can also wet the coal body, prevent spontaneous ignition of coal body, high-pressure water injection and crushing coal body, reduce pyrotechnic products, reduce costs, increase worker's sense of safety, use coal seam water injection hole sealer to break coal, can effectively prevent gas outburst and explosion.

User's manual

(1) The use of a seam sealer for coal seam water injection is quick and easy. Simply connect the waterway at the job site to the hole sealer, fully insert the hole sealer into the borehole, and under a certain pressure, the sealer hose expands to achieve hole sealing , Water injection and coal breaking.

(2) Connect the hole sealer to the underground static pressure water or high pressure water, insert the hole sealer into the coal seam hole to be injected with water, open the waterway safety valve, when the water pressure of the coal seam injection seam sealer reaches more than 1Mpa, rely on The hose of the sealer is expanded by static pressure water or high-pressure water pressure, and then the hole is filled. After the water injection is completed, the control water valve is opened to release the water in the pipe. When the pressure of the sealant drops below 0.5Mpa, the hole sealer It can be restored to its original state, and then the hole sealer is drawn out to complete the water injection work.

(3) The hole sealer for coal seam water injection can be used repeatedly for several times. After the water injection is completed, the pressure is removed, the hole sealer can be restored to its original state, and the hole sealer is taken out.

(4) Sending and inserting hole sealers and recycling hole sealers are strictly prohibited under pressure.

(5) No one is allowed to work directly in front of the hole sealer.