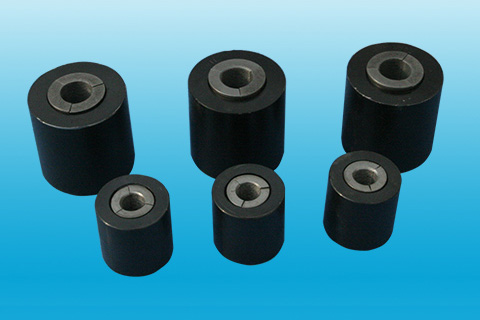

KM series anchor cable anchors consist of prestressed clips and anchor rings of different specifications. Product features: 1. High strength, large anchoring force, good stability; 2. Fast strength growth, can withstand load in time after installation; 3. Easy installation, low labor intensity of workers, high support efficiency, support cost and traditional support Compared with protective products, it is greatly reduced.

The main technical parameters

|

Specification model |

Anchorage bearing capacity KN |

Anchor efficiency coefficientηa |

Total strain εapu % |

Anchor Retraction value mm |

Fatigue performance test cycle (Ten thousand times) |

Ultimate tensile force of steel hinge wire KN |

|

KM22-1770 |

715 |

≥0.95 |

≥2 |

≤5 |

≥200 |

554 |

|

KM22-1860 |

940 |

≥0.95 |

≥2 |

≤5 |

≥200 |

582 |

|

KM15-1860 |

441 |

≥0.95 |

≥2 |

≤5 |

≥200 |

260 |

|

KM18-1860 |

544 |

≥0.95 |

≥2 |

≤5 |

≥200 |

355 |

Scope of application

KM series anchor cable anchors are mainly used in tunnels, tunnels and intersections with large surrounding rock deformation and poor geological conditions in coal mines, as well as surrounding rock fracture zones, stress concentration areas and other anchor cable support projects. Anchor cables used in building foundation pit reinforcement, slope treatment and various tunnels and bridges can also be used.

User's manual

(1) The installation work anchor plate should be consistent with the anchor pad stop, the work clip should ensure that the joints of the two pieces are the same size, the end face is neat, but it must not be beaten excessively to avoid damage.

(2) The limit plate and tool anchor should be matched with the corresponding working anchor plate and jack, and the limit size should be selected according to the prestressed tendons of different sizes and diameters. When the limit plate and the tool anchor are not matched with the jack stop, the backing ring should be used for centering. The outer surface of the tool clip and the inner hole of the tool anchor should be coated with a special anchor withdrawal spirit before use, so that the anchor is flexible.

(3) In the process of prestressed construction, protective devices should be provided in the danger zone. The operator should always stand on both sides of the component. It is strictly forbidden to stand in front of the anchor before the end. After the anchor is released, the anchor and For prestressed ribs, it is recommended to perform auxiliary prestressed rib cutting after grouting, and ensure that the anchor is not affected by the cutting force. It is best to use grinding wheel cutting and arc cutting is prohibited.

(4) The prestressed construction shall be organized by a professional unit with prestressed construction qualifications, and the technicians and operators responsible for tensioning shall obtain a certificate after professional training.