Product introduction and main parameters

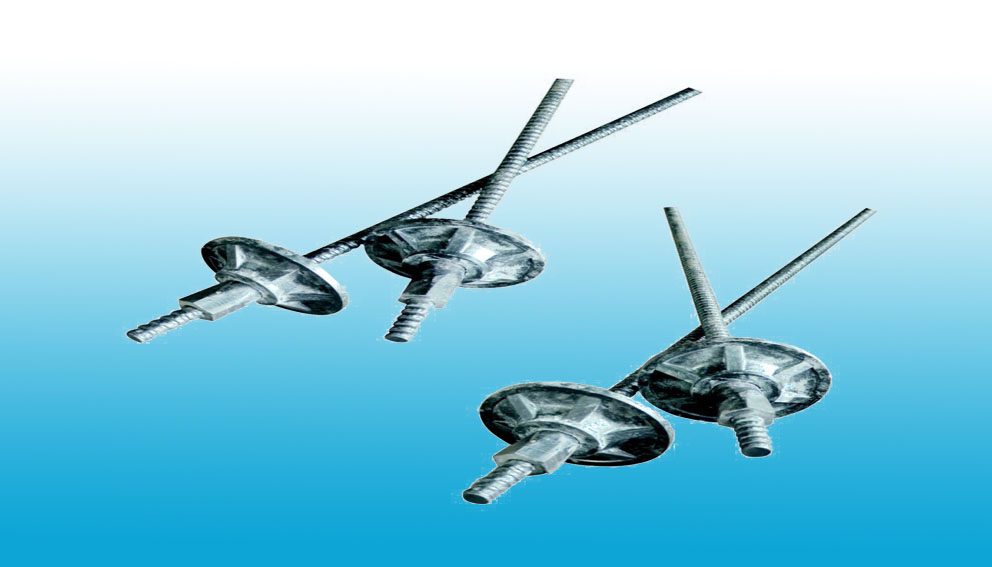

The main components of the fully threaded glass fiber reinforced anchor are the FRP anchor rod body, tray and nut. The FRP rod body is a full-thread structure with equal pitch. FRP anchor is a new generation of anchor developed in recent years. It has the characteristics of light weight, high strength, easy cutting without sparks, and no disassembly. It is an ideal support to ensure the safety of coal mine production and improve coal mining efficiency. material.

The main technical parameters

|

Tensile strength MPa |

Shear strength MPa |

Torque N·m |

|

≥300 |

≥75 |

≥40 |

|

Nominal diameter of rod(mm) |

16 |

18 |

20 |

22 |

|

Anchoring force, kN |

≥50 |

≥60 |

≥70 |

≥80 |

|

Thread carrying capacity ,kN |

≥50 |

≥60 |

≥70 |

≥80 |

|

Pallet carrying capacity, kN |

≥50 |

≥60 |

≥70 |

≥80 |

Scope of application

Full thread glass fiber reinforced anchors are mainly used for coal wall support in mining roadways and cutouts. The product has excellent physical and mechanical properties and corrosion resistance; light weight, transportation, loading and unloading, easy installation, easy to cut, no disassembly; flame retardant, antistatic performance, in line with coal mine safety requirements.

User's manual

(1) Construction process of FRP anchor rod: confirm hole position→drill hole in place→drill hole→clear hole→inject anchor agent→install anchor rod→install tray and nut→tighten nut.

(2) Determine the hole position, and the drilling position directly affects the installation quality and mechanical effect of the anchor rod. Therefore, the technician should determine the hole position according to the design requirements before drilling, mark the eye-catching mark, and drill the hole after accurate positioning.

(3) Drilling, according to the complexity of engineering geology, the bolt is drilled through the bolt machine, and the anchor is fixed by the reaction of the anchoring agent. After the drill bit of the bolt machine is drilled, the hole needs to be cleared to ensure the hole After cleaning, the anchoring agent can be injected.

(4) The installation of the anchor rod. When installing the anchor rod, the appropriate anchor rod should be selected. Different types of anchor rods have different functions on the use surface. During installation, the quality of the anchor rod must also be inspected, and the installation can only be carried out after passing the test.

(5) Put the anchor rod into the hole to see if the drilling rig has the proper depth. If it is not suitable, adjust the appropriate depth for installation.

(6) After the specified waiting time, the tray can be screwed on the nut. After the load time is reached, it can be tested.